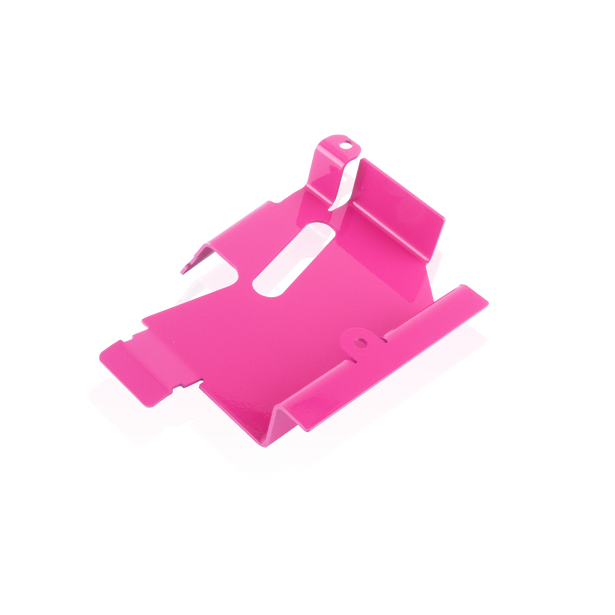

Complex sheet-metal components and precision cutting:

Top quality sheet-metal processing and laser cutting.

The services we provide as sheet-metal component manufacturers range from precision cutting to complex laser-cutting processes using ultra-modern facilities. State-of-the-art software converts 3D CAD data to direct programming 2D cutting data. This insures minimum wastage when laser-cutting i.e. optimum material utilization in the production of sheet-metal parts. High efficiency applied to sheet-metal processing is further enhanced by optimized processes facilitating unmanned shifts.

Our Amada facilities are appropriately programmed for folding operations. These incorporate Amada VPSS 3i 3D intelligent software solutions; bending processes can also be simulated to attain maximum precision. The resulting flexibility makes it possible for us to gear production to highly economical methods even in response to growing numbers of variants and smaller runs.

Divided top and bottom tools featured on our folding machines facilitate the production of highly complex designs. An extended stroke feature makes it possible to increase the side lengths of the sheet-metal parts – quite often a decisive factor – while the 6-axis limit stop system caters for secure positioning, even on misshapen components.

Benefit from our sheet-metal production and processing facilities geared to supreme quality standards and on-time solutions.

Examples of products:

Sheet-metal claddings, protective covers, mounting brackets, floor troughs, containers and holders.

Materials:

Low- and high-alloyed steels.

Your contact

Welcome to InProTec Sheet-metal processing

Thorsten Brugger

Head of sheet-metal processing division